Have you ever wondered how to make your own electronic components right at home? Imagine being able to create parts for your projects without waiting for deliveries or spending a fortune.

You don’t need a fancy lab or expensive tools—just some simple materials and clear steps. You’ll discover easy methods to build basic electronic components yourself. By the end, you’ll feel confident turning your ideas into real, working circuits. Ready to unlock this hands-on skill and take control of your electronics projects?

Let’s dive in!

Essential Tools And Materials

Basic tools like a soldering iron, multimeter, and wire cutters are needed for making electronic components. Common materials include copper wire, resistors, and circuit boards. These items help create and test simple electronics at home easily.

When creating electronic components at home, having the right tools and materials is crucial. You need to gather a few essential items to ensure your projects are successful. These tools and materials form the backbone of any DIY electronics endeavor. They help you build, test, and refine your projects with ease.Basic Equipment Needed

To start, you need a few basic tools. A soldering iron is vital for connecting components. Choose one with adjustable temperature settings for versatility. Wire cutters and strippers are essential for preparing wires. They help in cutting wires to the desired length. A multimeter is crucial for testing circuits and components. It measures voltage, current, and resistance. You also need a breadboard for prototyping circuits. It allows easy component swapping without soldering.Common Electronic Components

Stock up on common electronic components. Resistors control the flow of electric current. Capacitors store and release electrical energy. Transistors act as switches or amplifiers in circuits. Diodes allow current to flow in one direction. Integrated circuits (ICs) are tiny, complex circuits in a single package. LEDs are light-emitting diodes used as indicators. Collect these components to create diverse projects.Safety Precautions

Safety is paramount when working with electronics. Always unplug devices before working on them. Use insulated tools to prevent electric shocks. Wear safety goggles to protect your eyes from sparks. Work in a well-ventilated area to avoid inhaling fumes. Keep a fire extinguisher nearby in case of accidents. Double-check connections to prevent short circuits. Respect electricity and stay safe while creating.

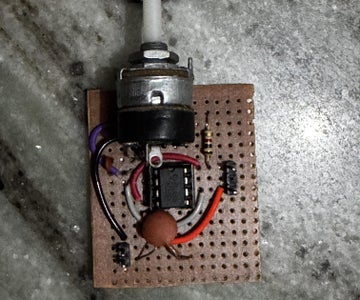

Credit: www.homemade-circuits.com

Preparing Your Workspace

Preparing your workspace is key to making electronic components at home. A neat and safe area helps you focus and work accurately. It reduces mistakes and keeps your parts safe. Take time to set up before starting any project. A well-organized space saves time and prevents accidents.

Organizing Tools

Keep all your tools in one place. Use small containers or trays for screws and tiny parts. Arrange tools by type and size. This makes finding what you need fast and easy. A clean workspace means fewer lost parts and less stress. Label containers to avoid confusion.

Ensuring Proper Lighting

Good lighting is crucial for detailed work. Use bright, white light to see colors and small parts clearly. Position lamps to avoid shadows on your work area. Natural light is great during the day. Poor lighting can cause eye strain and mistakes. Consider using an adjustable desk lamp.

Static Electricity Management

Static electricity can damage sensitive components. Use an anti-static mat to work on. Wear an anti-static wrist strap to ground yourself. Avoid working on carpeted floors. Keep humidity moderate to reduce static buildup. Handle parts by the edges to protect them from static discharge.

Creating Simple Components

Creating simple electronic components at home is easier than it seems. Basic parts like resistors, capacitors, and inductors are essential in many projects. Crafting these components by yourself can save money and deepen your understanding of electronics.

Using common materials and simple tools, you can make functional components. This hands-on approach helps you learn how each part works. Start with easy designs that require minimal equipment.

Making Resistors

Resistors control the flow of electric current. You can make a resistor using a pencil and paper. Graphite in pencil leads acts as a resistive material.

- Draw a long, thin line with a soft pencil on paper.

- Measure the resistance with a multimeter.

- Adjust the length or thickness to change resistance.

Another way is to use a thin wire, like nichrome, coiled around a non-conductive tube. The length and thickness of the wire affect resistance.

Building Capacitors

Capacitors store and release electric charge. You can create a simple capacitor with aluminum foil and paper. The paper acts as an insulator between two metal plates.

- Cut two pieces of aluminum foil of equal size.

- Place a thin piece of paper between them.

- Stack the layers and press firmly.

- Attach wires to each foil piece.

The size of the foil and thickness of paper affect the capacitance. Keep layers clean and dry for best results.

Crafting Inductors

Inductors store energy in a magnetic field. Making an inductor involves winding wire into a coil. The number of turns and coil size change its properties.

- Use insulated copper wire.

- Wrap it tightly around a cylindrical object like a pen.

- Count the turns and note the coil diameter.

- Leave extra wire ends for connections.

You can add a core of iron or ferrite inside the coil to increase inductance. Keep coils neat and evenly spaced for better performance.

Soldering Techniques

Soldering is a fundamental skill for making electronic components at home. It connects parts securely, ensuring your circuit works reliably. Mastering soldering techniques can save you time, avoid frustration, and improve the quality of your projects.

Choosing The Right Solder

The type of solder you pick affects how well your connections hold. Lead-free solder is safer and more common today, but leaded solder melts easier and flows better for beginners. Look for solder with a rosin core; the flux inside helps clean the metal surfaces as you solder.

Diameter matters too. Thin solder (around 0.7mm) gives you more control for small components, while thicker solder works faster on larger joints. Have you noticed how the right solder makes your work smoother and cleaner?

Basic Soldering Steps

- Heat the soldering iron and clean the tip with a damp sponge.

- Touch the iron tip to the joint where the component lead meets the circuit board.

- Apply solder to the heated joint, not directly to the iron.

- Let the solder flow smoothly and remove the iron once enough solder has melted.

- Allow the joint to cool without moving the parts to prevent cold solder joints.

It’s tempting to rush, but patience pays off. How often have you had to redo a joint because it looked dull or cracked?

Tips For Clean Joints

Keep your soldering iron tip clean by wiping it regularly on a damp sponge. Dirty tips cause poor heat transfer, leading to weak joints. Use just enough solder to cover the joint—too much can cause shorts, too little weak connections.

Work in a well-lit area and use magnification if needed to check your work closely. If a joint looks grainy or has gaps, heat it again and add a little more solder. What small changes can you make right now to improve your soldering quality?

Testing Your Components

Testing your electronic components is a crucial part of making reliable circuits at home. Without proper testing, you might end up with faulty parts that waste time and money. Taking the time to check each component ensures your project works smoothly and lasts longer.

Using A Multimeter

A multimeter is your best friend when testing components. It measures voltage, current, and resistance, helping you understand if a part is working correctly.

Start by setting your multimeter to the right mode. For resistors, use the resistance setting; for diodes, use the diode check mode.

Touch the probes to the component leads gently. If the reading matches the expected value, your part is good. If not, it might need replacement.

Identifying Faulty Parts

Spotting a bad component isn’t always obvious. Sometimes a capacitor looks fine but doesn’t store charge properly.

Look for signs like discoloration, bulging, or burn marks. These are clear clues of damage.

Use your multimeter to confirm suspicions. For example, a capacitor showing near-zero resistance may be shorted and unusable.

Ensuring Component Accuracy

Accurate components are essential for your circuit to function as intended. Even a slight deviation in resistance or capacitance can cause issues.

Compare your measured values with the component’s specifications. If you have multiple resistors, group them based on their actual resistance rather than just the color code.

Have you ever faced a project failure because a seemingly perfect component was off-spec? Testing helps you avoid such frustrating setbacks.

Credit: www.youtube.com

Troubleshooting Common Issues

Troubleshooting electronic components at home can feel challenging, but most issues are easier to fix than you might think. You’ll often find that simple adjustments or replacements can get your project back on track quickly. Let’s look at some common problems and how you can solve them effectively.

Fixing Connection Problems

Loose or faulty connections are the most frequent cause of electronics not working properly. Start by checking all solder joints and wires for any visible cracks or breaks. Using a multimeter to test continuity can help identify hidden connection faults.

If you spot cold solder joints—dull or cracked solder—reheat them carefully with your soldering iron and add a little fresh solder. Make sure wires are securely inserted into breadboards or connectors and avoid excessive bending that might weaken them over time.

Dealing With Overheating

Overheating components can damage your electronics and cause intermittent failures. Check if your components feel hotter than expected when powered on. If yes, give attention to your circuit design and cooling methods.

Adding small heat sinks or fans can dramatically reduce temperature. Also, verify that components are operating within their voltage and current ratings to avoid excess heat. Did you know even a tiny resistor placed strategically can help distribute heat more evenly?

Replacing Damaged Parts

Sometimes, parts just fail and need replacement. Identifying damaged components involves looking for burnt marks, discoloration, or unusual smells. Testing with a multimeter can confirm if a part is open or shorted.

Keep spare resistors, capacitors, and transistors handy for quick swaps. When replacing, ensure the new part matches the original’s specifications exactly. Have you ever replaced a transistor with one of a different rating only to find the circuit still misbehaves? Matching specs matters more than you’d think.

Projects To Practice Skills

Building electronics components at home is best learned by doing. Projects help you understand how different parts work together and sharpen your skills. Start with simple tasks and gradually take on more complex challenges to keep your learning curve steady and exciting.

Simple Circuit Builds

Begin with easy circuits like blinking LEDs or basic sound alarms. These projects teach you how to connect components such as resistors, capacitors, and transistors. You’ll gain confidence with soldering and reading circuit diagrams.

Try making a basic flashlight circuit or a touch-sensitive switch. These small wins build your foundation and show how small changes affect the circuit’s behavior. Have you tried modifying a simple circuit to see what happens?

Diy Electronic Gadgets

Once you’re comfortable, move on to creating your own gadgets. Build a temperature sensor or a homemade radio. These projects introduce microcontrollers and programming, adding a new layer of complexity.

Making a gadget you can use daily, like a USB charger or a digital clock, brings a sense of achievement. It also helps you understand how commercial products function under the hood. What everyday device would you like to build from scratch?

Upgrading Household Electronics

Improving existing electronics at home can be very rewarding. Add extra features to your old speakers or repair broken appliances with custom parts. This hands-on practice teaches troubleshooting and creative problem-solving.

For example, adding Bluetooth to a wired speaker or installing LED lights in a lamp can refresh old gear. This not only saves money but also reduces electronic waste. Which household item would you like to upgrade with your new skills?

Credit: www.instructables.com

Frequently Asked Questions

What Materials Do I Need To Make Electronics Components At Home?

You need basic materials like copper wire, resistors, capacitors, soldering iron, PCB boards, and a multimeter. These are essential for creating simple electronic circuits and components at home effectively.

Can I Create Complex Components Like Transistors At Home?

Creating complex components like transistors at home is very difficult and not practical. It requires specialized equipment and materials usually found in industrial settings.

How Can I Safely Solder Electronic Components At Home?

Use a soldering iron with a fine tip and work in a well-ventilated area. Wear safety glasses, avoid inhaling fumes, and handle hot tools carefully to prevent burns or accidents.

Is It Cost-effective To Make Electronics Components At Home?

Making simple components at home can save money and improve skills. However, complex parts are cheaper and more reliable when bought from manufacturers.

Conclusion

Making electronic components at home is simple and fun. Start with basic tools and parts you can find easily. Practice small projects to build your skills step by step. Safety is important, so work carefully and follow instructions. Creating your own components helps you understand how electronics work.

It saves money and allows you to customize parts as needed. Keep learning and experimenting to improve your results. With patience, anyone can make useful electronics at home. Give it a try and enjoy the process!

Leave a Reply