Are you tired of juggling endless maintenance tasks and struggling to keep your equipment running smoothly? Imagine having a simple tool that helps you track, schedule, and manage all your maintenance work in one place.

That’s exactly what an Electronic Maintenance Management System (EMMS) can do for you. You’ll discover how this powerful system can save you time, reduce costs, and boost your team’s efficiency. Keep reading to find out how you can take control of your maintenance process and make your workday easier.

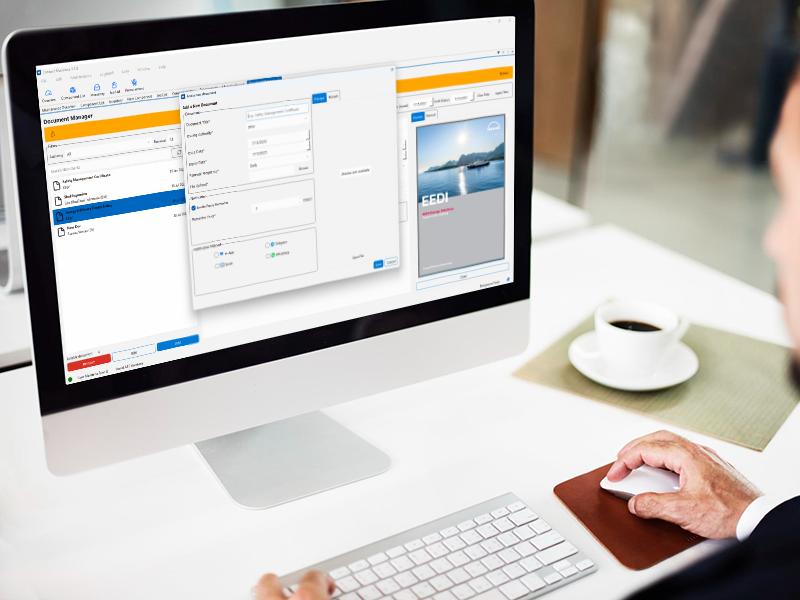

Electronic Maintenance Management System Basics

Understanding the basics of an Electronic Maintenance Management System (EMMS) is essential. It helps in managing and maintaining equipment efficiently. An EMMS automates and streamlines maintenance tasks. This system plays a crucial role in ensuring equipment longevity and reliability. Let’s dive deeper into its core functions, key components, and types.

Core Functions

An EMMS offers several core functions that enhance maintenance processes. It schedules preventive maintenance tasks to avoid unexpected failures. The system also manages work orders, tracking each step from creation to completion. Inventory management is another vital function, ensuring parts are available when needed. It provides real-time reporting, offering insights into maintenance activities and trends. These functions collectively improve operational efficiency.

Key Components

Several key components make up an effective EMMS. The database stores all maintenance-related information securely. The user interface allows easy navigation and use for all team members. A notification system alerts staff about upcoming tasks and deadlines. Integration capabilities ensure the system works smoothly with other business software. These components together form a robust maintenance management framework.

Types Of Systems

EMMS can be categorized into different types based on deployment and functionality. On-premise systems are installed locally and provide high control. Cloud-based systems offer flexibility and accessibility from any location. Mobile-enabled systems allow technicians to update tasks on the go. Each type caters to different organizational needs and preferences. Choosing the right type depends on specific requirements and resources.

Credit: www.accruent.com

Benefits Of Using Emms

Using an Electronic Maintenance Management System (EMMS) can transform how you handle your maintenance tasks. It streamlines processes, cuts down unnecessary costs, and helps keep your assets running longer. Here’s a closer look at the real benefits you can expect when you bring EMMS into your workflow.

Improved Efficiency

With EMMS, you get a clear overview of all maintenance activities in one place. This means less time chasing down information and more time fixing problems.

You can schedule work orders automatically and track progress in real-time. Imagine no longer having to rely on paper logs or manual reminders—everything updates itself.

Have you noticed how much time is wasted on coordination alone? EMMS helps you cut that down significantly.

Cost Reduction

EMMS helps spot inefficiencies that lead to wasted money. For instance, you can avoid emergency repairs by catching issues early.

It also reduces downtime by ensuring machines are maintained before they break. This keeps production steady and saves you from costly interruptions.

Think about the money spent on rushed fixes or buying replacement parts too soon. With an EMMS, your budget stretches further.

Enhanced Asset Lifespan

Regular, timely maintenance extends the life of your equipment. EMMS reminds you exactly when each machine needs attention.

This proactive approach prevents small issues from turning into big problems, saving you from premature replacements.

How long could your assets last if you never missed a maintenance task? EMMS gives you that kind of control.

Better Compliance

Keeping up with industry regulations can be overwhelming. EMMS tracks all maintenance records automatically, so you’re always audit-ready.

It helps you follow safety standards and maintenance schedules without extra effort. This reduces the risk of penalties or shutdowns.

Are you confident your current system keeps you compliant? An EMMS can give you peace of mind in this area.

Features To Look For

Choosing the right Electronic Maintenance Management System (EMMS) means knowing which features truly impact your daily work. The right tools can save you time, reduce errors, and boost your team’s productivity. Focus on core capabilities that address your specific maintenance challenges.

Work Order Management

Work order management is the heart of any EMMS. You want a system that lets you create, assign, and track work orders easily. Look for features like real-time updates and mobile access, so your team can stay connected on the go.

Imagine being able to instantly see which tasks are pending or completed without chasing down paper records. This clarity helps prevent missed deadlines and keeps your maintenance schedule on track.

Inventory Tracking

Keeping an accurate inventory of spare parts is crucial. An effective EMMS should track parts usage, reorder levels, and supplier details. This prevents downtime caused by missing components and helps you control costs.

Ask yourself: Does the system alert you before stock runs out? Automatic reorder notifications can save your team from last-minute scrambles and expensive emergency purchases.

Preventive Maintenance Scheduling

Preventive maintenance stops problems before they start. Your system should let you schedule routine checks and maintenance tasks based on time, usage, or condition. This reduces unexpected breakdowns and extends equipment life.

Think about how much smoother your operations could run if maintenance was planned, not reactive. Scheduling tools that send reminders help ensure nothing slips through the cracks.

Reporting And Analytics

Data drives smart decisions. A good EMMS provides detailed reports and analytics on equipment performance, maintenance costs, and work order history. This insight helps you identify trends and areas for improvement.

How often do you review maintenance data? Look for customizable reports that highlight key metrics important to your goals. Clear visuals and easy exports make sharing information with your team straightforward.

Credit: alvians.com

Implementation Strategies

Implementing an Electronic Maintenance Management System (EMMS) requires a clear strategy to ensure smooth adoption and maximum benefit. The process involves careful preparation, transferring existing data, training users effectively, and making sure the new system works well with your current tools. Each stage plays a vital role in helping your team get the most out of the investment.

Planning And Assessment

Start by evaluating your current maintenance processes and identifying areas that need improvement. Ask yourself what features your team truly needs and what challenges the system should address. This helps avoid buying unnecessary tools or overlooking critical functions.

Define clear goals and timelines to keep the project on track. Involve key stakeholders early to gather insights and build support. A well-thought-out plan reduces surprises and keeps everyone aligned.

Data Migration

Moving your existing maintenance records into the new system can be tricky. You must decide which data is essential and clean up outdated or incorrect information before transfer.

Test the data migration on a small scale first to catch errors early. This step saves time and frustration later. Remember, accurate data is the backbone of an effective EMMS.

User Training

Your system won’t work if users don’t know how to use it properly. Plan training sessions that fit your team’s experience and learning styles. Hands-on practice helps users feel confident and reduces resistance.

Offer ongoing support and refreshers. Encourage feedback to identify areas where users struggle. The easier the system feels, the faster your team will embrace it.

Integration With Other Systems

EMMS rarely works alone. It should connect smoothly with your existing tools like inventory management or accounting software. Integration streamlines workflows and avoids duplicate data entry.

Check compatibility and plan how information will flow between systems. A seamless connection saves time and prevents costly errors. Ask yourself: are your current systems ready to work together, or do they need adjustments?

Common Challenges

Electronic Maintenance Management Systems (EMMS) help organize and track maintenance tasks. Despite their benefits, many users face challenges during implementation and use. These common challenges can slow down adoption and reduce system effectiveness.

Understanding these issues helps businesses prepare better and handle problems effectively.

Resistance To Change

Employees often resist new systems. They prefer familiar tools and routines. Fear of learning new software can cause pushback. Training and clear communication are essential to ease this resistance.

Data Accuracy Issues

Accurate data is vital for EMMS success. Incorrect or incomplete data leads to wrong decisions. Regular audits and strict data entry rules improve accuracy. Clean data helps maintain system reliability.

System Downtime

System downtime disrupts maintenance schedules. It delays repairs and affects productivity. Reliable IT support and backup plans reduce downtime. Regular updates keep the system running smoothly.

Cost Overruns

EMMS projects can exceed budgets. Unexpected expenses arise from customization or training. Clear planning and budgeting control costs. Monitoring expenses during implementation prevents surprises.

Future Trends In Emms

The future of Electronic Maintenance Management Systems (EMMS) is full of innovation. New technologies will change how companies maintain their equipment and facilities. These trends help businesses save time, reduce costs, and improve efficiency. Understanding these trends gives a clear view of how maintenance will evolve.

Iot Integration

IoT devices connect machines and sensors to EMMS. This connection allows real-time data collection from equipment. It helps detect problems early and plan maintenance better. IoT integration reduces downtime and extends asset life.

Ai And Machine Learning

AI analyzes large data sets to predict equipment failures. Machine learning improves maintenance schedules based on past results. These technologies reduce unexpected breakdowns. They also help optimize resource use and improve decision-making.

Cloud-based Solutions

Cloud systems offer easy access to EMMS from anywhere. They provide secure data storage and automatic updates. Companies can scale their systems quickly without heavy hardware costs. Cloud solutions also support better collaboration across teams.

Mobile Accessibility

Mobile EMMS apps allow technicians to update tasks on the go. They can access work orders, manuals, and reports from their phones. Mobile access speeds up communication and fixes. It makes fieldwork more efficient and organized.

Credit: www.foodengineeringmag.com

Frequently Asked Questions

What Is An Electronic Maintenance Management System?

An Electronic Maintenance Management System (EMMS) is software that helps manage maintenance tasks. It tracks work orders, schedules preventive maintenance, and stores equipment data to improve efficiency and reduce downtime.

How Does Emms Improve Maintenance Efficiency?

EMMS streamlines maintenance workflows by automating scheduling and tracking. It reduces manual errors, speeds up task completion, and ensures timely repairs, enhancing overall equipment reliability.

What Are The Key Features Of An Emms?

Key features include work order management, asset tracking, preventive maintenance scheduling, reporting, and inventory control. These features help optimize maintenance processes and reduce operational costs.

Who Benefits Most From Using An Emms?

Industries with complex equipment like manufacturing, facilities management, and utilities benefit most. EMMS helps these sectors reduce downtime, increase asset lifespan, and improve maintenance team productivity.

Conclusion

An Electronic Maintenance Management System helps keep equipment in good shape. It saves time and reduces costs. Teams can track work and fix problems fast. This system makes maintenance simple and organized. Businesses run smoother with fewer breakdowns. Everyone knows what to do and when.

It supports smarter decisions and better planning. A good system brings clear benefits to any workplace.

Leave a Reply