Have you ever wondered how your computer systems, software, and networks stay reliable and run smoothly without constant breakdowns? The answer lies in something called Maintenance Information Technology.

Understanding this concept can save you time, money, and a lot of frustration. You’ll discover what Maintenance Information Technology really means, why it matters to you, and how it can protect your digital tools from unexpected problems. Keep reading to learn how to keep your technology working at its best, so you can focus on what truly matters.

Maintenance It Basics

Understanding the basics of Maintenance Information Technology (Maintenance IT) is crucial for anyone involved in managing business operations. It’s not just about fixing problems but optimizing the tools and systems that keep your business running smoothly. Let’s break down what Maintenance IT really means and why it matters to your daily work.

Definition And Scope

Maintenance IT refers to the use of technology to support the upkeep and repair of equipment, software, and infrastructure within an organization. It covers everything from routine checks to complex system updates that prevent breakdowns.

This field spans hardware maintenance, software updates, and network management, ensuring all technological assets perform efficiently. Think of it as the backbone that keeps your digital and physical tools reliable.

Key Components

- Monitoring Systems:Tools that track the health and performance of your equipment in real-time.

- Data Management:Storing and analyzing maintenance records to predict future issues.

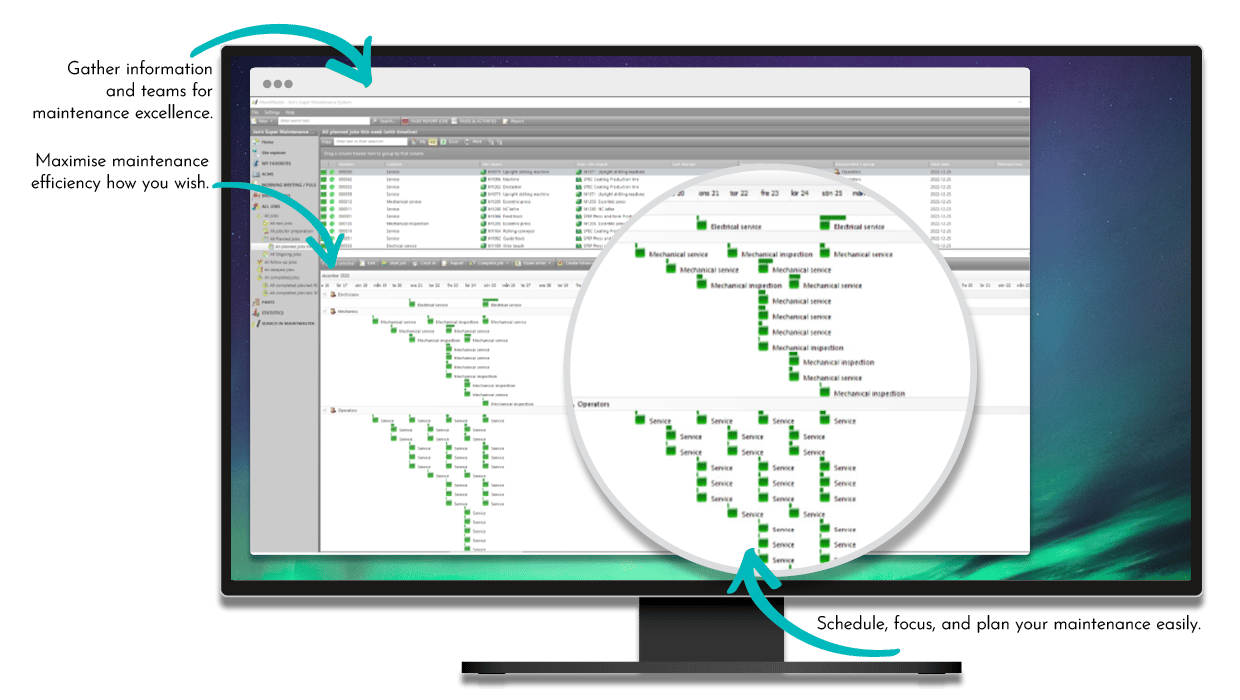

- Automation Tools:Software that schedules and executes maintenance tasks automatically.

- Communication Platforms:Systems that help coordinate maintenance teams and alert stakeholders quickly.

Each component plays a role in reducing downtime and extending the life of your assets. Imagine how much easier your day would be if you knew when a machine or system needed attention before it actually failed.

Importance In Modern Business

Maintenance IT directly impacts your business’s productivity and costs. When your systems are well-maintained, you avoid unexpected breakdowns that disrupt workflows and drain resources.

Efficient Maintenance IT also helps you plan better by providing clear data on when and what maintenance is needed. This means you can allocate your budget wisely and keep your team focused on growth rather than firefighting.

Have you ever faced a sudden system failure that halted your work? Maintenance IT aims to prevent those moments and keep your business running without surprises.

Credit: terotam.com

Types Of Maintenance It

Understanding the types of Maintenance Information Technology (IT) can help you keep your systems running smoothly and avoid costly downtime. Each type targets different stages of equipment care and offers unique benefits. Let’s break down the main types so you can decide which fits your needs best.

Preventive Maintenance

Preventive maintenance is all about scheduling regular checkups and updates before problems arise. You might set reminders to update software, check hardware health, or clean components. This approach reduces unexpected failures and extends the life of your equipment.

Think about your car: you change the oil and rotate the tires regularly to avoid breakdowns. The same idea applies here. Wouldn’t it be better to fix a small glitch now than face a total system crash later?

Predictive Maintenance

Predictive maintenance uses data and smart tools to anticipate when an issue might happen. Sensors and monitoring software analyze performance trends and alert you to potential failures. This means you fix problems exactly when needed, not too early or too late.

Imagine getting a notification that your hard drive is showing signs of wear before it actually fails. That heads-up lets you back up your data and replace the drive without losing anything important. How much downtime could you save by catching issues early?

Reactive Maintenance

Reactive maintenance happens after something breaks or stops working. It’s the “fix it when it breaks” approach. While this can save time and money upfront, it often leads to longer disruptions and higher repair costs.

If your server crashes unexpectedly, you scramble to get it back online, affecting your users and business operations. Have you noticed how costly emergency repairs can be compared to planned maintenance?

Technologies In Maintenance It

Maintenance Information Technology uses modern tools to improve how equipment is cared for. These technologies help predict problems, reduce downtime, and save costs. They make maintenance faster and smarter.

Internet Of Things (iot)

IoT connects machines and sensors to the internet. This connection allows real-time monitoring of equipment. Sensors send data about temperature, vibration, and wear. Maintenance teams get alerts before failures occur. This reduces unexpected breakdowns and extends machine life.

Artificial Intelligence And Machine Learning

AI and machine learning analyze data from machines to find patterns. They predict when parts might fail or need service. These technologies help plan maintenance at the best time. AI reduces human error and improves decision-making. It makes maintenance more efficient and cost-effective.

Cloud Computing

Cloud computing stores maintenance data online. Teams can access information from anywhere at any time. It supports real-time collaboration and faster decision-making. Cloud platforms also handle large amounts of data easily. This technology improves data security and backup.

Credit: www.knightoffice.com

Benefits Of Maintenance It

Maintenance Information Technology (IT) offers a range of benefits that directly impact how businesses manage their equipment and operations. By using IT solutions, you can save money, boost your team’s efficiency, and extend the life of your machinery. Let’s look at these benefits more closely to see how they can improve your daily work and bottom line.

Cost Reduction

Using Maintenance IT helps you cut costs in several ways. It allows you to schedule maintenance only when needed, preventing unnecessary repairs and downtime. This targeted approach reduces emergency fixes, which are often expensive and disruptive.

Imagine avoiding a major breakdown because your system alerted you early about a potential issue. This kind of proactive maintenance saves you money on parts and labor while keeping your operations running smoothly.

Enhanced Productivity

Maintenance IT tools streamline your workflow by organizing tasks and tracking progress automatically. Your team spends less time on paperwork and more on actual maintenance work.

With real-time data and alerts, you can prioritize urgent jobs and allocate resources effectively. This leads to faster response times and fewer interruptions, making your workday less stressful and more productive.

Increased Equipment Lifespan

Regular and well-planned maintenance powered by IT extends the life of your equipment. When you catch small problems early, you prevent them from turning into bigger, more costly issues.

Think about how a machine that receives timely care can operate longer without breakdowns. This means you get more value from your investments and avoid the hassle of frequent replacements.

Challenges And Solutions

Maintenance Information Technology faces many challenges that can slow down progress. Addressing these issues is key to smooth operations and better results. Solutions focus on improving security, system compatibility, and workforce skills.

Data Security Concerns

Protecting sensitive data is a top priority. Maintenance IT systems store valuable information, making them targets for cyber attacks. Strong encryption and regular security updates help keep data safe. User access controls limit who can see or change data. Frequent security training for staff reduces risks from human error.

Integration With Existing Systems

Many companies use old software and hardware. New maintenance IT tools must work well with these older systems. Using open standards and APIs allows different systems to connect smoothly. Testing before full rollout helps catch compatibility issues early. A phased implementation plan avoids major disruptions.

Skill Gaps In Workforce

Technology changes fast, but worker skills may lag behind. Training programs build the needed knowledge for new maintenance IT tools. Hiring specialists can fill urgent gaps. Encouraging team learning creates a culture of continuous improvement. Clear documentation supports employees as they adapt to new systems.

Future Trends In Maintenance It

The future of Maintenance Information Technology (IT) is shaping how businesses keep their equipment and systems running smoothly. New trends are not only making maintenance faster and smarter but also more aligned with global sustainability goals. Are you ready to see how these changes can transform your maintenance strategy?

Advancements In Automation

Automation is becoming a key player in maintenance IT. Smart sensors and robots now handle routine inspections and repairs, reducing downtime and human error.

Imagine a system that detects a machine fault before it causes a breakdown and automatically schedules repairs. This proactive approach saves money and keeps your operations running without interruption.

Role Of Big Data Analytics

Big data analytics helps you make sense of vast amounts of maintenance data. By analyzing patterns, you can predict failures and optimize maintenance schedules.

For example, some companies use data to identify which parts wear out fastest, allowing them to stock the right spare parts. This cuts costs and speeds up repairs, improving overall efficiency.

Sustainability And Green Technology

Maintenance IT is increasingly focused on sustainability. Energy-efficient systems and eco-friendly materials are becoming standard in maintenance processes.

How can you reduce your environmental footprint while maintaining high performance? Green maintenance technology offers solutions that lower waste and energy use without sacrificing quality.

Case Studies

Case studies offer real-world examples of Maintenance Information Technology in action. They show how different companies use technology to improve their maintenance processes. These stories help us understand what works and what doesn’t. Learning from actual experiences saves time and money.

Successful Implementations

Many companies have improved efficiency using Maintenance IT systems. One factory cut downtime by 30% after installing predictive maintenance tools. Another business reduced repair costs by tracking equipment health with IoT sensors.

Key benefits seen in these cases include:

- Faster issue detection

- Lower maintenance expenses

- Better resource planning

- Improved asset lifespan

These successes highlight the impact of smart maintenance strategies. Technology makes maintenance proactive, not reactive.

Lessons Learned

Some companies faced challenges during implementation. Common issues were poor data quality and lack of staff training. These problems slowed progress and caused extra costs.

Lessons from these cases include:

- Ensure clean, accurate data before starting

- Train employees on new systems

- Start with small pilot projects

- Keep communication open across teams

Understanding these lessons helps avoid common mistakes. It leads to smoother adoption of Maintenance IT tools.

Credit: maintmaster.com

Frequently Asked Questions

What Is Maintenance Information Technology?

Maintenance Information Technology involves using IT tools to manage and support equipment upkeep. It helps track maintenance schedules, automate tasks, and improve system reliability. This technology streamlines maintenance processes, reducing downtime and operational costs efficiently.

How Does Maintenance It Improve Equipment Lifespan?

Maintenance IT monitors equipment health and schedules timely repairs. It detects issues early, preventing major failures. By optimizing maintenance tasks, it extends equipment life and enhances performance, saving businesses money on replacements and repairs.

What Are Common Tools Used In Maintenance It?

Common tools include Computerized Maintenance Management Systems (CMMS), IoT sensors, and predictive analytics software. These tools collect data, automate work orders, and provide insights to improve maintenance efficiency and decision-making.

Why Is Data Important In Maintenance Information Technology?

Data helps identify patterns and predict equipment failures before they occur. Accurate data enables better maintenance planning, reduces unexpected downtime, and increases operational efficiency. It is crucial for informed decision-making in maintenance strategies.

Conclusion

Maintenance Information Technology helps keep systems running smoothly. It reduces downtime and saves money. Businesses can spot problems early and fix them fast. Teams work better with clear data and tools. This field grows as technology changes. Understanding it helps companies stay efficient and safe.

Simple steps in maintenance lead to big benefits. Staying updated is key to long-term success.

Leave a Reply